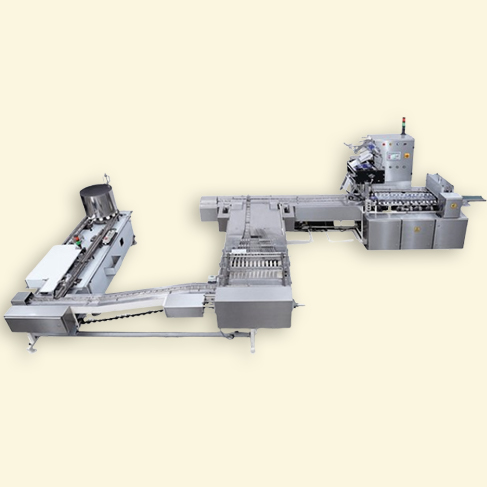

Cream Right Angle Automation Manufacturers, Suppliers, and Exporters in India, South Africa, Paarl, Johannesburg, Benin, Zambia, Central Africa, Uganda, Mozambique, Kenya, Nairobi, Nigeria, and Lagos. Cream Biscuit Auto feeding is one of the best revolutionary solutions in biscuit industries for packaging of different types of packets. Semiautomatic with hopper feeding from cream sandwiching machine to packaging machine. Servo operated feeding unit make it very effective and reduce the man power to a certain limit. The PLC controlled with touch screen panel make it user friendly and is easy to set the parameters. The speed can be varied up to 140 packets per minute according to stack lengths and biscuit dimensions.

| Main Drive Motor | 3 phase 6 Lead | 1.5 KW, 1440 rpm, 440 V, 50 Hz |

| Paper Drive Servo Motor | 1 phase | 0.4 KW, 3000 rpm, 220 V, 50 Hz |

| Cream Machine Servo Motor | 3 phase | |

| Merging Unit Servo Motor | 1 phase | 0.4 KW, 3000 rpm, 220 V, 50 Hz |

| Servo Drive | Single phase – 1 no | 200 V, 400 W |

| Main Drive VFD | 230 V, 2 HP | Input – single phase | Output – 3 phase |

| Jaw Heater | 50 V, 175 W – 8 No | |

| Dish Heater | 50 V, 400 W – 4 No | |

| Transformer | Primary - 2 Phase, 440 V , Secondary – 50 V, 30 A + 30 A | |

| Product Size Range | 50 mm (W) x 28 mm To 60 mm (W) x 60 mm (Ht) |

| No of Sandwiches | 4 to 10 in one pack |

| Wrapper Size Range | 110 to 290 mm Cutoff Length & 150 to 300 mm wrapper width |

| Type of Product | Should be stiff or hard and round or rectangle or square in shape. |

| Speed | 40 to 140 (PPM) (depending upon the size of the stack length). |

| Feeding | Auto stacking & feeding |

| Weight | 1500 kg (Approx.) |

| Wrapping Material | BOPP laminated. LD Polyester. Heat Sealable Laminates Containing Aluminum Foil. Maximum 12" Roll diameter |